What Is GRP Roofing?

What Is GRP Roofing?

GRP (Glass Reinforced Polyester) came into being during the letter end of the 1940’s.

It consists of interwoven glass fibres to which a polymer is added then cured to produce a lightweight, extremely strong and robust material.

During the 1950’s and 60’s, GRP was readily adopted for a whole host of applications where its high strength, corrosive-proof properties and excellent appearance proved to be invaluable. One of the first applications GRP was used for was in boat building, where it is still widely used today.

GRP has also been used as a waterproofing material for more than 5 decades on boats, car and truck bodies, water tanks, ponds, pools and roof lights.

And because GRP can withstand high temperatures and is resistant to chemicals, it is also used in hostile industrial settings for underground pipes and tanks.

Sixty years on, the use of GRP is commonplace as a trusted method for the construction of boats, building panels, water tanks, roof lights and high performance waterproof coatings.

And in the last ten years, there has been rapid growth in the use of GRP for roofing applications as the advantages of GRP for Leyland homeowners have become more widely recognised.

What is a GRP Roof?

What is a GRP Roof?

When used to build a boat, GRP provides complete waterproofing protection for the craft’s entire lifespan of over 20 years without the need for maintenance or replacement.

That’s why GRP is great for roofing where this same level of performance is easily replicated.

In roofing applications, a properly constructed GRP roof will last for at least 30 years on your Leyland property with no measurable deterioration.

Typically following these steps:

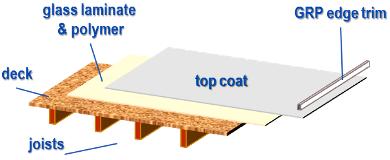

– A deck made from OSB3 (orient strand boards) is laid on joists

– Glass laminate is laid on top of the deck

– Polymer resin is applied

– Pre-formed GRP edge trims are fixed in place

– Finally, a finishing top coat is applied

Unlike other roofing materials, GRP has properties that make it admirably suited to construction. It is an inexpensive robust material that is flexible and will never rot away or corrode.

If you’re thinking about having a GRP roof for your property in Leyland, please get in touch and we will explain the process and provide a competitive quote.